- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 1

- Place of Origin: jinan

- Brand Name: Fangxin electronic

- Model Number: 1

- Weight: 1.000 kg

Sensing element catalytic sensor and infrared sensor or electric chemical formula sensors

Measuring range % LEL for combustible gas, PPM for gas, vol % of O2 and CO2

12 to 24 VDC power supply voltage - 20% + 15%

12 VDC power consumption in 90 ma (general); 130 ma (Max); Depends on the models

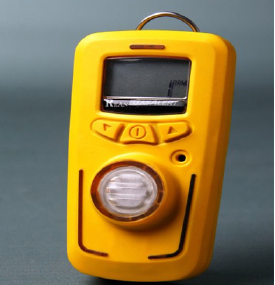

A visual indicator blinking leds

Proportion of output 1 (2) x 4-20 mA (300 Ω; largest Ω general 300)

Maximum load 200 Ω

Serial output (optional) RS 485 for addressable control host and related agreement

Relay output (optional) 3 switch relay contact without tension capacity 24 v - 1 a

Automatic zero zero drift compensation program

Digital filtering average value of each sample

Resolution 4096

Display (mode) 4, 5 mm high, 2, 5 mm wide eight lattice letters show

< accuracy + / - 5% full scale (in accordance with IEC 60079-29-1). Usually < 2% of full scale

Repetitive < plus or minus 2% of full scale

Preheat time for 5 minutes

Stable time < 2 minutes

Response time t-50 < 20 SEC., T90 < 60 seconds (conform to IEC 60079-29-1);

In general: t-50 < 10 seconds., T90 < 30 seconds.

Storage temperature to 25 ° C present + 60 ° C

Working temperature averaged 20 ° C - present + 55 ° C (different models or have a wide range, specific see detector label)

Relative to 20-90% RH / 40 ° C

Working pressure. 80-110 KPa

Degree of protection IP65

Air speed < 6 ms

Weight of 2500 g. (Max.)

Guard dog Used for internal microprocessor condition monitoring

Overall dimensions See note figure size

Installation direction detector probe always down

ATEX certified reference detector corresponding ATEX certification information, please refer to the goods provided by the safety instruction manual.

EMC compatibility reference standard EN 50270:2006 EN 61000-6-3:2007

The use of toxic gas alarm

Toxic gas alarm system is composed of detector and alarm control host, widely used in petroleum, gas, chemical industry, oil depot with toxic gas such as petrochemical industry, used to detect leakage, indoor and outdoor dangerous sites is an important equipment to ensure production and personal safety. When measured place existence of poisonous gas, gas detector will signal into a voltage or current signals to the alarm instrument, the instrument shows that the percentage of the toxic gas explosion lower limit density. When the concentration of toxic gases than alarm value occurs when sound and light alarm signal, the personnel on duty in a timely manner to take safety measures to avoid explosion accidents.

1. The points for attention during the application

Poisonous gases alarm fixed installation once in place, is not easy to change its position, the following points should be considered when concrete application.

(1) to figure out what to monitor device may leak, analysis their leakage factors such as pressure, direction, and draw the probe location map, according to the severity of the leak into Ⅰ, Ⅱ, Ⅲ three levels.

(2) according to the places where specific factors such as the airflow direction, the direction of the wind, to determine when a large number of leakage, leakage of poisonous gas.

(3) according to the density of gas leak (greater than or less than air), combined with the trend of air flow, integrated into a leakage of the three-dimensional flow trend diagram, and in the flow downstream of the initial instruction plan.

(4) the leak leakage state is slightly leaking or injection. If it is slightly leaking, then the location of the instruction will be closer to leak. If the leakage is spurting, slightly away from the leak point. Comprehensive these conditions, work out the final instruction. So, need to purchase the number and variety of estimate.

(5) for there is a big place for toxic gas leak, according to the relevant provisions of the every 10-20 m should be set apart a checkpoint. For small unmanned and discontinuous operation of pump room, need to pay attention to the possibility of a toxic gas leakage, generally a detector should be installed in the tuyere.

(6) for a place with hydrogen leakage, should install over the leak detector plane.

(7) for medium gas density than air, down to the bottom of the detector should be installed below the leak in the plane, and pay attention to the surrounding environment. In place for the accumulation of toxic gases should pay special attention to setting of safety monitoring.

Escape (8) to open the toxic gas diffusion environment, if the lack of good ventilation conditions, it is easy to make certain parts of toxic gas in the air content is close to or reach the lower explosive limit concentration, these are not to be ignored safety monitoring. According to the analysis of the site accident, more than half of them are caused by incorrect installation and calibration. Therefore, it is necessary to introduce the correct installation and calibration of matters needing attention in order to reduce fault.

2. The toxic gas alarm installation considerations

(1) alarm sensor is mainly contact burning gas sensor detecting element, by platinum silk bag of alumina and glue ball, on the outer surface with platinum, palladium and other precious metals. Therefore, must be careful when installing, avoid broke the probe.

(2) the installation height of the alarm should be in commonly 160-170 cm, in order to repair personnel for routine maintenance.

(3) instrument alarm is safe, sound and light show function, shall be installed where the staff is easy to see and hear, so as to timely eliminate hidden dangers.

(4) alarm cannot have affected the instrument work around the strong electromagnetic fields (such as high power motors, transformers).

(5) of the gas density is different, indoor probe installation position should also be different. Measured gas density is less than the density of air, the probe shall be installed outside the 30 cm away from the roof, down direction. On the other hand, the probe shall be installed at 30 cm away from the ground, upwards.

- Size: 1

- Place of Origin: jinan

- Brand Name: Fangxin electronic

- Model Number: 1

- Weight: 1.000 kg